Isikhungo sokuqala sokusekelaukukhanya kwangaphandlekufanele kube ibhokisi lokusabalalisa ngaphandle. Sonke siyazi ukuthi kunohlobo lwebhokisi lokusabalalisa elibizwa ngebhokisi lokusabalalisa elingangeni manzi kuzo zonke izigaba zamabhokisi okusabalalisa, futhi amanye amakhasimende aphinde alibize ngebhokisi lokusabalalisa elivimbela imvula. Eqinisweni, lolu hlobo lwebhokisi lokusabalalisa lusetshenziswa kakhulu ngaphandle ukuvimbela Isimo Sezulu esinokhahlo, okokuqala, akudingekile ukusho ukuthi ibhokisi lokusabalalisa elingangeni manzi kumele libe nomsebenzi wokuvikela uthuli futhi lingangeni manzi, futhi lidinga nokuba nomsebenzi wokumelana ne-asidi ne-alkali, kanye nezimfuneko zezinga lokuvikela nazo ziphezulu kakhulu, futhi idinga ukufinyelela i-IP66.

Ufuna ukwazi ukusetshenziswa kwemishini evamile nezinto zokwakha zensimbi engagqwali yangaphandleukukhanya kwangaphakathi? Uyini umehluko phakathi kwezinto zebhokisi lokusabalalisa ezisetshenziswa kuyoukukhanya kwangaphandle?

Esikhathini sokuqala sohlelo, kufanele sicabangele indawo yokufaka kanye nomthwalo kagesi webhokisi lokusabalalisa. Kuphrojekthi yangaphambilini, ngenxa yokungacatshangelwa okwanele, indawo yokwakha yayivame ukukhungatheka (ukuphakama okuphezulu kwamamitha angaphezu kuka-300, ibhokisi lokusabalalisa izibani lalibekwe endaweni engafanele, futhi iningi lezibani nezibani zazikhungathekile. Ibekwe endaweni eyodwa ophahleni, futhi kunezibani zokusesha zamandla aphezulu ezingaphezu kweshumi nambili, esigabeni sokuqala sephrojekthi ehlongozwayo ukusetha uphahla lokukhanya).

Ukukhethwa kwezinto zegobolondo lebhokisi lokusabalalisa: Ngokuvamile, izinto ezihlukahlukene zikhethwa endaweni yokusetshenziswa kanye nezindleko zomkhiqizo; okujwayelekile emakethe ngokuyinhloko kuyizinto zensimbi, futhi izinto ezijwayelekile zimi kanje:

Ishidi eligoqekile elibandayo le-SPCC:Ukwelashwa okungaphezulu kusebenzisa i-electroplating kanye nopende wokubhaka, onezindleko eziphansi futhi kulula ukuwenza. Ugqinsi lwempahla lungaphansi noma lulingana no-3.2mm. Njengamanje iyona esetshenziswa kakhulu, ibalwa cishe ngama-80% emakethe.

Ishidi eligoqelwe ngokushisayo i-SHCC:Ukwelashwa okungaphezulu kusebenzisa izingxenye ze-electroplating nepeyinti, okuyizindleko eziphansi, kodwa okunzima ukuzenzela. Ubukhulu bezinto ezibonakalayo ≥3.0mm, futhi izingxenye eziyisicaba zisetshenziswa kakhulu.

Ithusi:Ukwelashwa okungaphezulu kufakwe nge-nickel, kufakwe i-chrome, noma akulashwa, futhi izindleko ziphezulu.

Insimbi engagqwali:Indawo engaphezulu ayiphathwa, izindleko ziphezulu, kodwa ibonakala ngomsebenzi omuhle wokulwa nokugqwala futhi ihlala isikhathi eside, ifaneleka ngokukhethekile ukusetshenziswa ezindaweni zangaphandle.

Ipuleti le-Aluminium:Ukwelashwa okungaphezulu ngokuvamile kusebenzisa i-chromate ne-oxidation (i-conductive oxidation, i-chemical oxidation), ebiza kakhulu, kodwa inezici zokumelana nezinga lokushisa eliphezulu, ukumelana nokugqwala, kanye nokufakwa kahle, ngakho kuphephe kakhulu.

Iphrofayili ye-aluminium:impahla enesakhiwo esiyinkimbinkimbi se-cross-sectional, esisetshenziswa kakhulu kumabhokisi amancane ahlukahlukene. Ukwelashwa okungaphezulu nokusebenza kuyafana nepuleti le-aluminium.

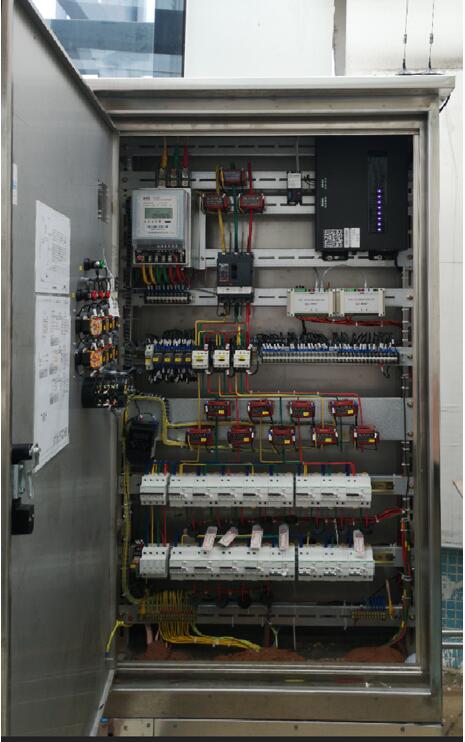

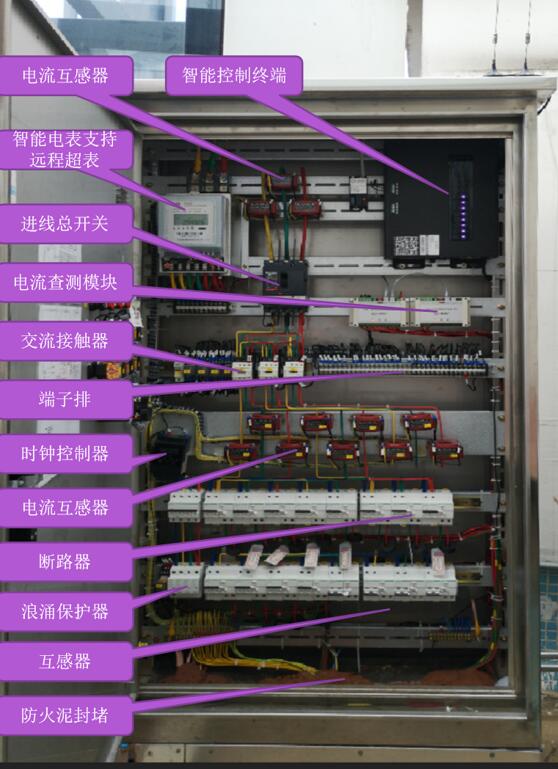

Lapho ufaka ibhokisi lokusabalalisa endaweni engaphandle, izinga lokuvikela akufanele libe ngaphansi kune-IP54, futhi isisekelo akufanele sibe ngaphansi kuka-300mm ngaphezu komhlaba. Isithombe esilandelayo sibonisa umdwebo wokwakha webhokisi lokusabalalisa:

Izithombe ezingezansi ziyisithombe sangempela sebhokisi lokusabalalisa. Uma ubhekisisa, kunezimpondo eziningi kanye nama-receptors ezithombe zamehlo ahlanganisiwe kuwo.

Isikhathi sokuthumela: Sep-28-2022